Georgia On Our mind: The Evolution of the “Flooring Capital of the World”

A Historical Overview

Georgia, often recognized for its peaches, pecans, and southern charm, also holds a prominent position in the carpet and flooring industry. This industry, deeply rooted in Georgia's history, has evolved significantly from its early days, experiencing remarkable growth, technological advancements, and a strong emphasis on sustainability. It is home to significant US based manufacturing jobs and operations and is a true innovation hub, akin to Silicon Valley.

“The numbers back it up. In 2021, more than 55 percent of flooring industry establishments were in Georgia, along with the industry’s three largest operators. More than 150 carpet plants call Georgia home, and our state alone accounted for 72.1 percent of the industry’s total wages and 70 percent of the total employment last year.” (Governor Brian Kemp as shared with Floor Covering Weekly)

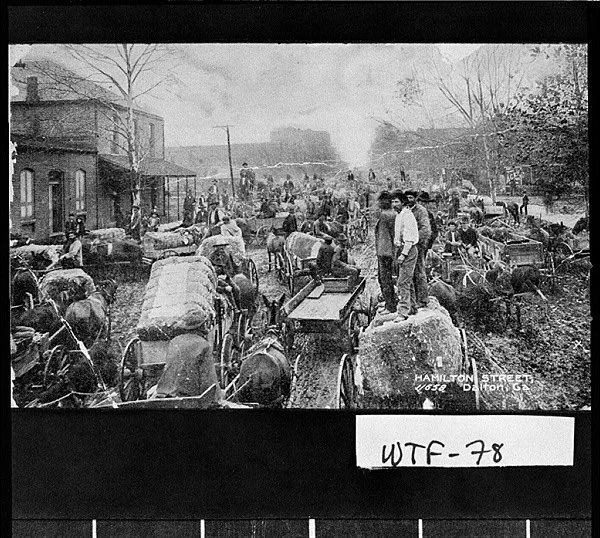

Hamilton Street, Dalton

Courtesy of Georgia Archives.

Early Beginnings: 1875-1940

The story of Georgia's carpet and flooring industry begins in the late 19th century. In 1875, William Sprague opened the first carpet mill in Dalton, Georgia. Although initially a small operation, this mill marked the beginning of a long and prosperous journey for the region. The early 20th century saw incremental growth, with more mills opening and contributing to the local economy.

During this period, the production process was labor-intensive and relied heavily on wool. The mills produced simple, hand-woven carpets that catered to local demand. However, as technology advanced, so did the methods of production, laying the groundwork for a more industrialized approach.

Don Draper’s Mad Men Office

Mid-20th Century Boom: 1940-1970

The carpet industry in Georgia saw a significant boom during and after World War II riding the rising tide of expansive US business growth. Jobs grew not only in factories but now also in new offices, schools, and hospitals on the commercial side. Residential interest grew as families sought inexpensive, comfortable carpets to brighten their homes. Innovations in synthetic fibers, particularly nylon, also revolutionized carpet manufacturing. In 1947, the introduction of tufting machines allowed for faster production at lower costs. This period marked the transformation of Dalton, Georgia, into the "Carpet Capital of the World."

The 1950s and 1960s were characterized by rapid expansion. Many families put a stop in Dalton on their summer travel plans to explore and buy new carpets as this era unfolded. By 1960, Dalton was producing over 80% of the world’s carpet. The industry became the backbone of the local economy, providing jobs and spurring infrastructural development. Companies like Shaw Industries and Mohawk Industries, which are now industry giants, established their roots during this period.

Mannington’s elegant, functional style award featured in Interior Design

Mannington's Role in the Industry

One of the notable players in the flooring industry with a significant presence in Georgia is Mannington Mills. Founded in 1915 in Salem, New Jersey, Mannington expanded its operations to Georgia, recognizing the region’s growing importance in the flooring market. Mannington has been instrumental in driving innovation and sustainability within the industry. In addition to its growth, it is uniquely American as a fifth-generation owned family business. (Fun fact: less than 3% of businesses make it past the fourth generation.)

The Era of Technological Advancements: 1970-2000

The latter half of the 20th century witnessed remarkable technological advancements in the carpet and flooring industry. The development of continuous dyeing processes in the 1970s allowed for more vibrant and long-lasting colors. This period also saw the rise of computer-aided design (CAD) systems, enabling intricate patterns and designs that were previously impossible.

During the 1980s and 1990s, the industry continued to evolve with the introduction of stain-resistant treatments and the use of recycled materials. Ray Anderson of Interface was a part of the force that helped introduce sustainability as both an imperative and business differentiator in the early 1990s.

Emphasis on Sustainability: 2000-Present

In the last two decades, sustainability has become a major theme in the carpet and flooring industry. Companies have recognized the importance of reducing their environmental footprint and have made significant strides in this area.

Mannington Mills, for example, has been at the forefront of sustainability efforts. The company has implemented numerous initiatives aimed at reducing waste, conserving water, and lowering emissions. Mannington's Loop™ recycling program, launched in 2006, focuses on recycling post-consumer carpet into new products, thereby reducing landfill waste.

Working Together

While each company in this ecosystem serves their own customers and has their own focus, there are significant ways they work together. For example, under the guidance of the Carpet and Rug Institute, many flooring companies have successfully collaborated to institute a rigorous recycling program, C.A.R.E. Initiated two decades ago, C.A.R.E. is focused on recycling carpet thus diverting it from landfills, which had evolved into an increasing sustainability concern. Carpet is low mass/high volume and takes up space in landfills. Since then. C.A.R.E. has diverted hundreds of millions of pounds of carpet from landfills, redirecting the embodied energy in old carpet into long lasting engineering materials for automotive, building materials and other uses.

Major Breakthroughs in the Industry

The 21st century has seen several major breakthroughs in the carpet and flooring industry, many of which have strong ties to Georgia:

Recycling and Reuse:

Companies like Shaw Industries introduced the Evergreen Nylon Recycling Facility in 1999, capable of recycling post-consumer carpet back into its original fiber form. This closed-loop recycling process has set a standard for sustainability in the industry.

Sustainable Materials:

The introduction of sustainable materials such as bio-based fibers and adhesives has reduced reliance on petroleum-based products. For example, Mohawk’s SmartStrand carpet, introduced in 2005, uses a renewable polymer derived from corn sugar.

Energy Efficiency:

Advances in manufacturing technology have led to more energy-efficient production processes. Companies have invested in renewable energy sources, such as solar and wind power, to reduce their carbon footprint.

Digital Printing Technology:

The advent of digital printing technology in the 2010s allowed for high-definition patterns and designs, offering greater customization and aesthetic appeal. This technology has revolutionized the production of luxury vinyl tile (LVT) and other flooring products.

Indoor Air Quality:

Innovations in low-VOC (volatile organic compounds) adhesives and finishes have improved indoor air quality, addressing health concerns associated with traditional flooring materials.

Mannington’s beautiful downtown Atlanta showroom

The Role of Technology and Innovation

Technological advancements have played a crucial role in shaping the carpet and flooring industry in Georgia. Automation and robotics have streamlined production processes, enhancing efficiency and consistency. Computer-aided design (CAD) and digital printing have expanded design possibilities, allowing for more intricate and personalized flooring options.

Moreover, the use of data analytics and smart manufacturing technologies has optimized supply chains, reducing waste and improving overall sustainability. Companies can now monitor and adjust their processes in real-time, ensuring optimal resource utilization and minimizing environmental impact.

Smart flooring is a new realm in this journey, enabling flooring leaders to not only focus on a sustainable supply chain or recycling practices, but to now have their carpeting and flooring products to contribute to significant energy savings, evolving flooring into a competitive and significant bonus.

Evolution of beautiful design, inspired by nature

Conclusion

The history of the carpet and flooring industry in Georgia is a testament to the region's resilience and innovation. From its humble beginnings in the late 19th century to its current status as a global leader, the industry has continually evolved to meet the demands of consumers and the environment.

Scanalytics own VP of Materials & Flooring and long-time Georgia resident Keith Gray reflects, “Based on my almost 30 years of experience in the flooring business, it is my belief that this industry is characterized by its resilience and ability to adapt and serve its customers as well as to embrace new technologies to evolve. The flooring industry in Georgia is a brilliant example of the importance of visionary leadership, US based skills and manufacturing and innovation in an ever-changing world.”

Looking forward, the future of flooring includes exciting innovations led by the established leaders and (relative) newcomers like Scanalytics. New, patented technology like smart flooring, which incorporates sensors and connectivity to enhance functionality, not only reduces energy consumption by 35% but also enables “smart buildings” that adapt and best serve its human occupants. As the industry continues to grow, the legacy of Georgia's carpet and flooring sector remains strong, paving the way for a smarter, more sustainable future.