The Second Renaissance of American Manufacturing: From Industrial Revolution to Smart Innovation

The story of American manufacturing is a tale of innovation, leadership, and adaptation. From the thundering machines of the Industrial Revolution to today's cutting-edge smart technology, the United States has repeatedly reinvented its manufacturing identity. Now, as we witness a resurgence in domestic production, it's worth examining this journey and understanding why bringing manufacturing back home matters more than ever.

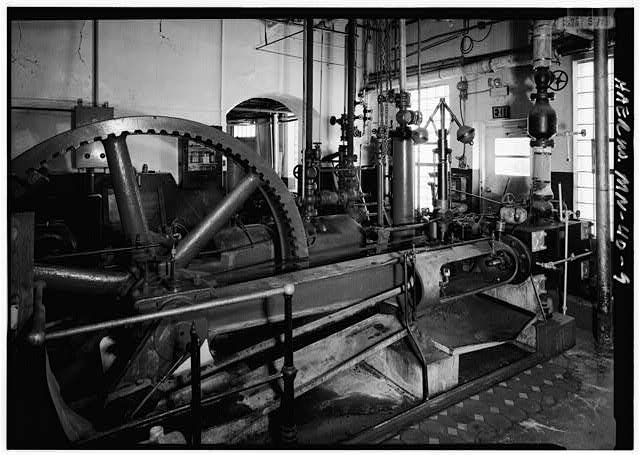

The Foundation: Industrial Revolution to Post-War Boom

The American Industrial Revolution transformed a largely agrarian society into a manufacturing powerhouse. Cities like Detroit, Pittsburgh, and Chicago became industrial hearts pumping innovation through the nation's economic veins. However, it was the post-World War II era that truly cemented America's manufacturing dominance.

With Europe and Japan rebuilding from the war's devastation, American factories stood unscathed and ready to supply the world. The 1950s and 1960s saw unprecedented growth, with "Made in USA" becoming a global symbol of quality and innovation.

The Golden Age of American Electronics

Perhaps nowhere was American manufacturing prowess more evident than in the electronics sector of the 1960s and 1970s. Take printed circuit boards (PCBs), for instance. Companies like Texas Instruments and Motorola led the world in PCB manufacturing, with innovations that would become the backbone of the modern electronics industry. In 1965, Gordon Moore, co-founder of Intel, predicted the doubling of components on integrated circuits every two years – a prediction that held true for decades and drove American semiconductor dominance.

Another shining example was the development of automated manufacturing processes for electronic components. Companies like IBM pioneered surface-mount technology in their domestic facilities, revolutionizing electronics assembly and miniaturization.

The Offshore Shift

However, by the late 1970s and early 1980s, the manufacturing landscape began to shift. Several factors contributed to this change:

Rising Labor Costs: American workers' wages and benefits had grown substantially, making overseas production more attractive to corporations focused on bottom-line profits.

Global Competition: Countries like Japan had rebuilt their industrial base with newer, more efficient facilities.

Environmental and Regulatory Costs: Stricter U.S. regulations, while important for worker safety and environmental protection, added to production costs.

Emerging Market Access: Companies saw opportunities to manufacture closer to growing Asian markets while taking advantage of lower costs.

By the 1990s and 2000s, many American manufacturers had moved production overseas, particularly to China and Southeast Asia. The trend seemed irreversible, and with it went not just jobs, but crucial technical expertise and innovation capabilities.

The Pendulum Swings Back: Manufacturing's Return

Today, we're witnessing a remarkable reversal of this trend. The reasons are compelling:

Supply Chain Vulnerability: The COVID-19 pandemic exposed the risks of over-reliance on distant suppliers

Rising Overseas Costs: Labor costs in traditional manufacturing countries have increased significantly

Automation: Advanced robotics and AI have reduced the labor cost advantage of overseas production

Quality Control: Proximity to design and engineering teams improves product quality and innovation

Environmental Concerns: Shorter supply chains reduce carbon footprints

National Security: Critical industries need domestic production capabilities

Smart Flooring: A Case Study in American Manufacturing Innovation

One exciting example of this manufacturing renaissance is the smart flooring industry, where American companies are leading the way in innovation and domestic production. Take Scanalytcs, a pioneer in smart flooring technology that has committed to 100% U.S. manufacturing. Their smart flooring systems, which can track movement patterns and gather valuable data for healthcare, retail, and security applications, represent the future of American manufacturing – high-tech, innovative, and locally produced.

Traditional flooring giants like Tarkett and Mannington are also part of this story. These companies have maintained significant U.S. manufacturing presence while incorporating smart technology into their products. By partnering with tech innovators like Scanalytcs, they're proving that American manufacturing can successfully combine traditional expertise with cutting-edge technology.

Looking Forward

The return of manufacturing to American soil isn't just about nostalgia or nationalism – it's about building a more resilient, innovative, and sustainable future. Smart flooring is just one example of how American manufacturers can lead in emerging technologies while keeping production domestic.

As we move forward, the key to success will be embracing advanced manufacturing techniques, investing in workforce training, and maintaining the innovative spirit that made American manufacturing great in the first place. The new "Made in USA" label doesn't just represent a product's origin – it represents a commitment to innovation, quality, and sustainable manufacturing practices.

The renaissance of American manufacturing is underway, and it's being built not on the old model of mass production, but on smart, sustainable, and technologically advanced foundations. As companies like Scanalytcs demonstrate, the future of American manufacturing is not just about making things – it's about making things smarter.